All our products are designed with a user-centric approach. Our goal is to develop products that exceed our customers’ expectations. Every industry, every site, and every customer is unique, with their own challenges, needs, and goals. Together, we address these challenges, find solutions that meet your needs, and work together to achieve the goal of providing better, more efficient, and sustainable solutions.

Our focus is on your safety in hazardous environments.

At the turn of the millennium, largely due to poor-quality products, LED luminaire’s reputation was quite poor. Often, low-quality and cheap imported products did not meet the requirements of Finnish industrial sites. This raised doubts in the minds of buyers and customers. Fortunately, modern high-quality LED luminaires have convinced buyers to demand the use of LED luminaires.

We argue that the most significant selling points for LED luminaires have always been ease of use and longevity. Price arguments are always present in negotiations, and LED luminaires are no different in this regard. When operating in EX-classified environments, longevity, maintenance-free operation, and reliability are paramount in our opinion. However, the product’s price should still be reasonable. How can this balance be achieved?

Due to the product certification alone, EX environments, which react somewhat more slowly than other industrial sectors, have also transitioned to using LED luminaires. What should be examined more closely in LED luminaires designed for EX environments?

First and foremost, check the ATEX classification or code. Has the product even been certified? Does the device even apply to the required environment? If so, how is it built? If it has an Ex d protected enclosure, is the connection area also Ex d structure, or has installation been facilitated, for example, by an Ex e structure? Has the light output produced by LED technology been considered, and has the optical radiation produced by the luminaire been restricted?

LED technology has introduced new challenges when considering lighting in EX environments. The efficiency of light output from “old technology luminaires” has remained almost constant for many years. However, LED technology can improve the efficiency of the light source almost every year. This, in itself, creates a unique risk factor for EX environments. It is crucial to check whether the luminaire is equipped with the “Ex op is” marking. This marking simply means that the optical radiation from the light source has been considered in the luminaire’s design and certification.

Why is this important? When thinking about industrial sites as environments, cleanliness is not necessarily the first thing that comes to mind. Luminaires are often dirty. If dirt accumulates on the luminaire’s surface and the threat of optical radiation has not been considered, the dirt could ignite.

The simplest example of this is a magnifying glass and the sun. If sunlight is focused through a magnifying glass, the resulting optical radiation can ignite the target. A similar chain of events can also occur with powerful LED luminaires and the optical radiation they produce. The intensity of the radiation can ignite an explosive dust or gas mixture.

Therefore, it is of paramount importance that when selecting luminaires and examining light output, consideration is given to whether the luminaire’s optical radiation has been considered in the product’s design.

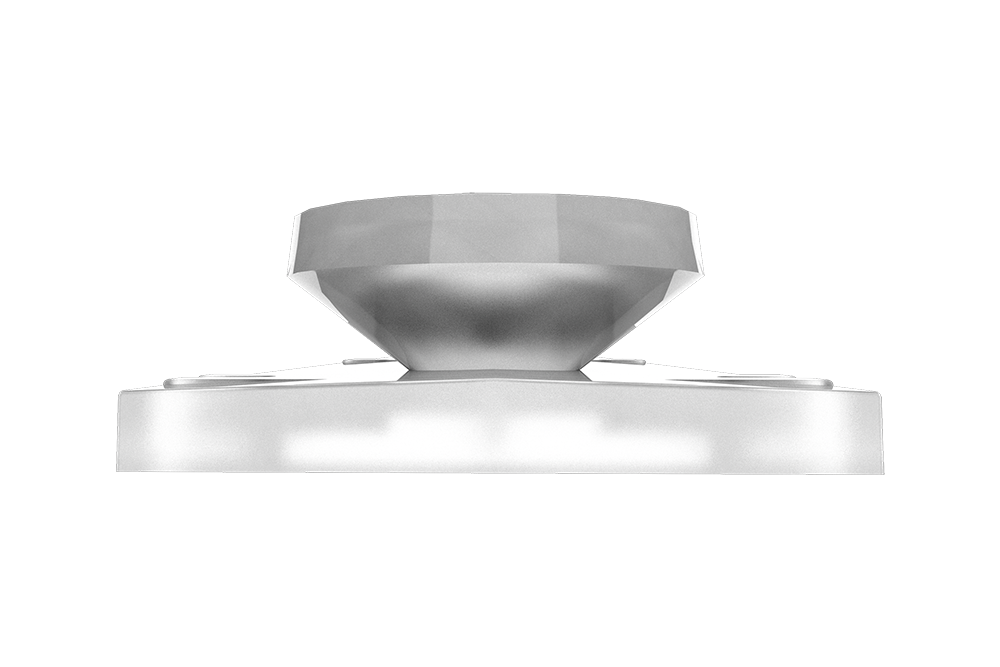

Jukolux Oy’s ATEX luminaires JUKO HX/ALX take into account the significance of optical radiation. Extremely reliable and powerful high-power LEDs ensure a long service life and a high light output. The unique LED optics, developed in collaboration with the leading industry expert LEDil, are the result of ATEX expertise and optical design.

When ATEX electrical equipment is certified, their enclosures must be tested forimpact resistance according to the basic standard 60079-0. Impact tests are performed by dropping a 1 kg weight onto the enclosure at the most unfavorable location. The impact must not cause any changes to the enclosure.In other words, the enclosure must withstand the impact. The force of the impact is determined according to the intended use, and the product can be tested with either high or low impact force. Luminaires of equipment group II, except for light-emitting parts, are tested with either 4J or 7J force.

So why should attention be paid to this? If a luminaire has been tested for a low-impact force, it must be installed considering the additional requirements created by the low-impact force. Often, this is expressed in the conditions of use of the certificate: “The product must be installed in a way that protects it from external mechanical impacts.”

What makes this particularly interesting is that if a luminaire has been tested for a high-impact test (i.e., 7J), but it does not come with suitable cable entries, and the customer unknowingly installs a cable entry that is suitable for a low-impact test (4J), the product must be installed according to the weakest component, which means it should be protected from external mechanical impacts.

For this reason, Jukolux Oy’s luminaires are always supplied with suitable cable entries and sealing plugs.