On this page, we will discuss ATEX environments and the illumination of ATEX areas. We will also cover ATEX LED lights.

Below is a list of the most common terms encountered when discussing ATEX, ATEX lighting, and lighting in general.

An EU directive concerning equipment and work in areas where explosive atmospheres are handled. (Abbreviation: ATmosphères EXplosibles)

Indicates the required level of protection in explosive atmospheres.

Indicates the maximum surface temperature of an ATEX light.

Measured in lumens (lm), it tells you how much light is emitted from a light source.

How many lux do you need? Illuminance is measured in lux (lx) and tells you the value of light falling on a surface. Technically, 1 lux is 1 lumen per square meter.

Simply put, the brightness of a point or surface of light in a specific direction.

Specified in Kelvins (K), it describes whether the light is “warm” (below 4000K) or “cool” (above 4000K).

CRi (Ra index). It indicates the light source’s ability to accurately render colors. The value is given as a number from 0 to 100, with 100 being the best.

Lumens per watt (lm/W) is a measure of a light fixture’s efficiency. It tells youhow many lumens are produced per watt of power consumed.

What does the term “ATEX lighting” mean? Areas where explosive substances are handled are always risky, requiring the use of ATEX-approved equipment. The ATEX directive is an EU directive that pertains to working and equipment in these hazardous areas. An EX/ATEX light is a light that is permitted to be used in explosive atmospheres. However, it’s not enough for a light to be ATEX-approved. The ATEX light must also be suitable for use in the specific explosive environment, based on more detailed specifications. Therefore, the following information about the light must also be checked:

We will now delve into these sections in more detail, laying the foundation for how to read ATEX classification and, most importantly, what can be deduced from it.

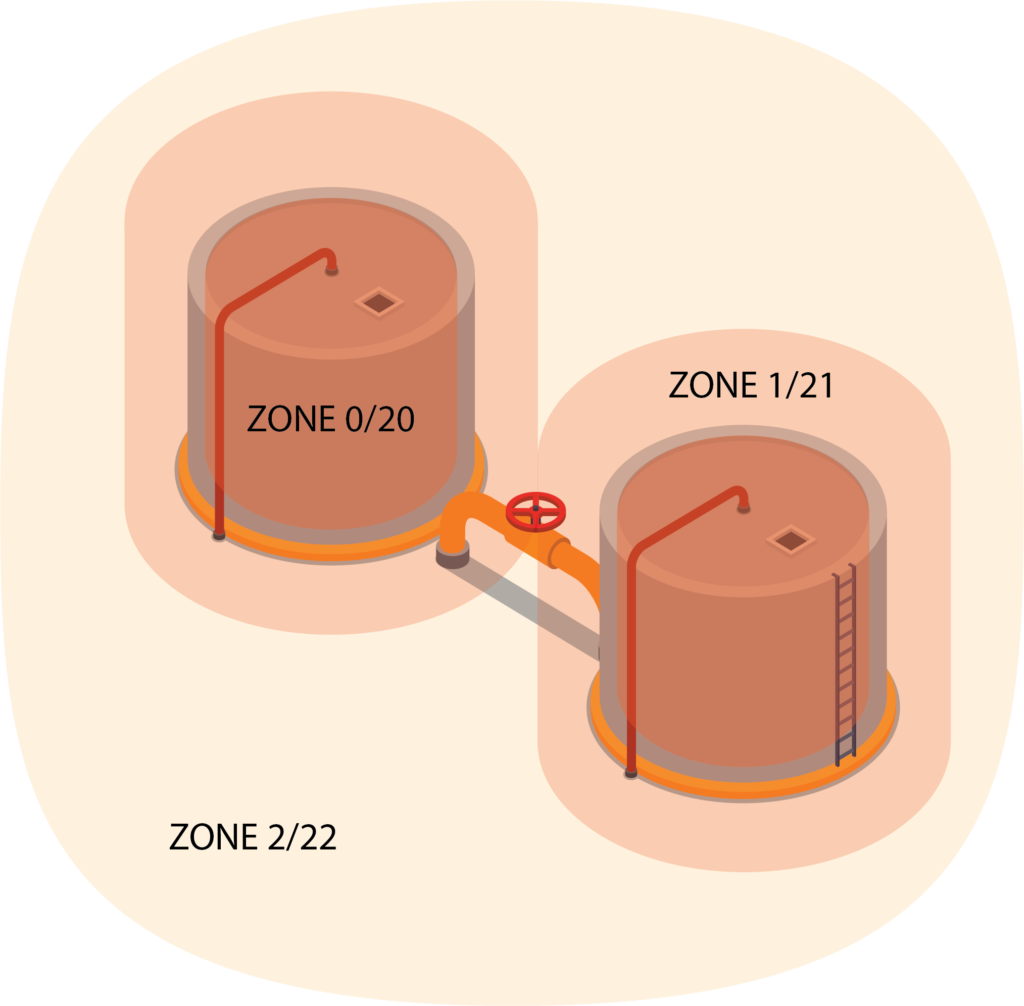

ATEX ZONES are categorized into two main groups: gas and dust zones. Gas zones are denoted by numbers 0, 1, 2, and dust zones by numbers 20, 21, 22. Devices suitable for ATEX zones are indicated by category numbers 1, 2, and 3.

0/20 zones require category 1 devices due to very high ignition sensitivity.

Zone 0 is an area where an explosive atmosphere, formed by the presence of air and flammable gases, vapors, or mists in the form of a cloud, is present continuously, for long periods, or frequently. Zone 20 is an area where an explosive atmosphere formed by a mixture of air and flammable dust, present continuously, for long periods, or frequently.

1/21 zones require category 2 devices due to high ignition sensitivity.

Zone 1 is an area where an explosive atmosphere is likely to occur in normal operation due to the presence of flammable gases, vapors, or mists. Zone 21 is an area where an explosive atmosphere is likely to occur in normal operation due to the presence of flammable dust.

2/22 zones require category 3 devices with normal ignition sensitivity.

Zone 2 is an area where an explosive atmosphere is not likely to occur in normal operation but, if it does occur, will persist for a short period. Zone 22 is an area where an explosive atmosphere is not likely to occur in normal operation, but if it does occur, it will exist for only a short time.

ATEX EQUIPMENT GROUPS are divided into two main groups. Equipment Group I is suitable for use in mining conditions, while Equipment Group II is suitable for industrial conditions but not for mines. If a device is suitable for both groups, it will have a specific type code for each group.

Equipment suitable for mining conditions (Group I) is further divided into two subgroups: M1 (can be used continuously in the presence of mine gases) and M2 (can be switched off in the presence of mine gases).

All EX/ATEX lights also have an ATEX TEMPERATURE CLASSIFICATION. This classification indicates the maximum surface temperature of the product.

EXPLOSION HAZARD GROUPS can be divided into two main groups: gas and dust groups. The “G” (gas) designation refers to gas groups, while “D” (dust) designates dust groups. Both main groups can be further divided into subgroups, depending on the type of dust or gas present in the air.

Gas Groups G

Dust Groups D

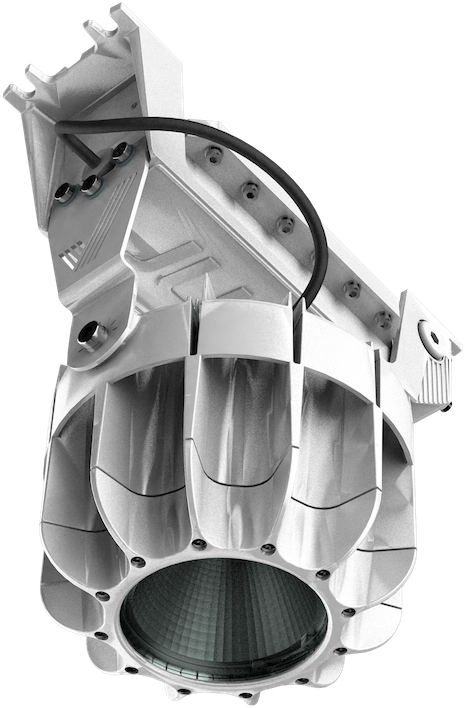

The above markings largely form the product’s ATEX code, which can be used to determine which areas the product is suitable for. For example, the Jukolux Oy JUKO HX product is equipped with the following code:

Ex II 2G Ex db eb op is IIC T5 Gb (gas environments)

Ex II 2D Ex tb op is IIIC T95°C Db ((dust environments)

Tamb = -40°C to +40°C

The code means:

Let’s take a closer look at protection methods and what Ex db eb op actually means. All information is based on the standards for electrical equipment in explosive atmospheres, which are the IEC/EN 60079 series of standards. The basic requirements for luminaires (and other electrical equipment) are covered by standard 60079-0, although this standard is not explicitly represented in theluminaire’s ATEX code with any letters. It contains general requirements that form the basis for the design of electrical equipment.

Protection against explosions for luminaires, as well as other electrical devices, can be built on two fundamental principles. Either ensuring that dangerous temperatures or sparks do not occur, or isolating dangerous temperatures or sparks so they cannot ignite an explosive mixture outside the device. To prevent the generation of temperature and sparks, increased safety (Ex e) and intrinsic safety (Ex i) can be used. To isolate dangerous temperature or sparks, flameproof construction (Ex d), quartz/sand-filled construction (Ex q), oil-immersion (Ex o), pressurized construction (Ex p), and encapsulation (Ex m) can be utilized.

In our designs, we employ protection methods Ex e, Ex d, and Ex m from the methods presented above. Additionally, we use a tight enclosure construction Ex t suitable for dusty environments. Our luminaire designs also take into account the intense light radiation produced by LED technology. As a result, every product we manufacture is protected against hazards caused by optical radiation, using Ex op is protection.

Here’s a more detailed explanation of each protection method:

Contains the pressure, quench the flame.

The idea behind this construction is to maintain overpressure inside the enclosure, which prevents an explosive mixture from coming into contact with parts that may cause ignition.

Parts that can ignite an explosion are placed inside an enclosure filled with oil in a way that prevents the hazardous parts from coming into contact with an explosive mixture.

Components are placed inside an enclosure filled with a powdery substance (usually sand), in such a way that ignition is quenched.

This protection method is suitable for low-power devices with power requirements so low that they cannot ignite an explosive mixture in fault conditions. This situation is achieved by limiting the current and voltage in the circuit to values that are not hazardous and cannot cause sparks or hot surfaces.

Parts that can cause hazards are encapsulated preventing them from coming into contact with an explosive mixture. The standard defines requirements for the encapsulant in terms of its properties and use.

The goal is to limit the optical radiation emitted by devices so that it does not ignite an explosive mixture.

The construction must be dust-tight (practically IP6X) so that explosive dust mixtures do not come into contact with parts that could cause hazards. The surface temperature of the enclosure is also limited to prevent it from becoming a potential source of ignition.